Steaming of Green Tea - how is it done and why?

Green and black tea are produced from the same plant - Camelia Sinensis. Although there are subspecies (cultivars or varieties) that are used primarily for green tea or for black tea, it is ultimately not the cultivar but the processing that determines whether the tea plant becomes green tea, black tea or perhaps oolong tea.

In the production of green tea, heating the freshly harvested tea leaves stops fermentation, i.e. the withering of the tea leaves. If the fermentation is allowed to run its course, the result is first a half-fermented tea (oolong) and finally black tea.

A significant impact of the process used on the taste and ingredients of the tea becomes clear when comparing Japanese and Chinese green teas. Chinese green tea is traditionally dry-heated in large pans, while in Japan the tea leaves are exposed to hot steam. These steamed Japanese teas are often summed up simply as sencha.

Steaming methods are now also used outside of Japan, so there are also senchas from other regions. On the other hand, pan-dried teas are also produced in Japan, where they are called "kamairicha."

In addition to the differences in taste, the gentle steaming of the leaves also preserves the active ingredients in the best possible way. This is evident, for example, in studies of EGCG content, in which Chinese (pan-dried) teas tend to have lower levels than Japanese green teas.[1].

However, there are also differences among steamed teas depending on the intensity and duration of steaming.

From the beginning, our partners at Shimodozono Japan have placed great emphasis on achieving the best possible aroma whilst also bringing as many of the valuable ingredients of the fresh tea leaf as possible into the cup and making them available to the body.

In order to achieve this, steaming methods have been continuously improved over the years. You can tell the degree of steaming by the steaming symbols on the tea boxes:

Apart from Irimushi steaming, the tea leaves of Shimodozono teas are steamed directly after harvest at about 100°C. Due to short distances, a maximum of freshness can be preserved.

The different steaming methods for each KEIKO tea is marked on the tea box:

![]()

Asamushi is the light steaming with a duration of 30-45 seconds and is sometimes referred to as Futsūmushi), or normal steaming.

Asamushi teas usually have a light cup color and a rather light aroma compared to more steamed teas.

In the KEIKO assortment, Asamushi teas are rather rare guests - most recently, for example, the Shincha Yakushima is only lightly st

![]()

Chūmushi (or Chumushi) is the intermediate steaming with a duration of 45-60 seconds and is used at KEIKO for Kabuse No.1, for example (previously Fukamushi).

However, the majority of KEIKO teas are Fukamushi teas - Fukamushi is the intense steaming with a duration of 60-90 seconds. However, the majority of KEIKO teas are Fukamushi teas - Fukamushi is the intense steaming with a duration of 60-90 seconds.

The more intense the steaming, the more the cell structure of the tea leaves is broken down, so more ingredients are released during the infusion. Fukamushi teas can therefore be recognized by their rather small, matt leaves compared to the sometimes long, shiny needles of some Asamushi teas, and by the fact that they develop a particularly deep green color with a high suspended matter content in the infusion, while lightly steamed teas and especially the Chinese roasted teas usually have a clear, light, often yellowish cup.

In terms of taste, the more intensive steaming is noticeable through a more intense aroma - even at low temperatures or even cold infusions, the intensively steamed leaves release their aroma even with a comparatively short infusion time.

We have linked some examples of Fukamushi teas in the KEIKO range below this post!

However, the exact duration of steaming also depends on the nature of the leaves. Finer leaves can be steamed for a shorter time, while firmer leaves need either more time or a completely different approach.

In recent years, Shimodozono has therefore laid a special focus on optimizing the Irimushi steaming method. In this process, the sheets are steamed on special equipment at a higher temperature but for a shorter time. The efficiency could be increased so that the leaves are steamed very evenly. The enzymes that otherwise trigger fermentation are very reliably deactivated, and even in the case of coarser leaf material (for example, from later pluckings or cultivars with a strong leaf structure), the aroma could be intensified and the color improved. The active ingredient content is also fully exploited with this method.

Irimushi steaming is mainly used for Benifuuki, Bancha and teas from the later pickings in summer and autumn.

The right method and the right degree of steaming are therefore crucial both for exploiting the active ingredient potential of the tea plant and for the aroma.

Related products

Average rating of 4.7 out of 5 stars

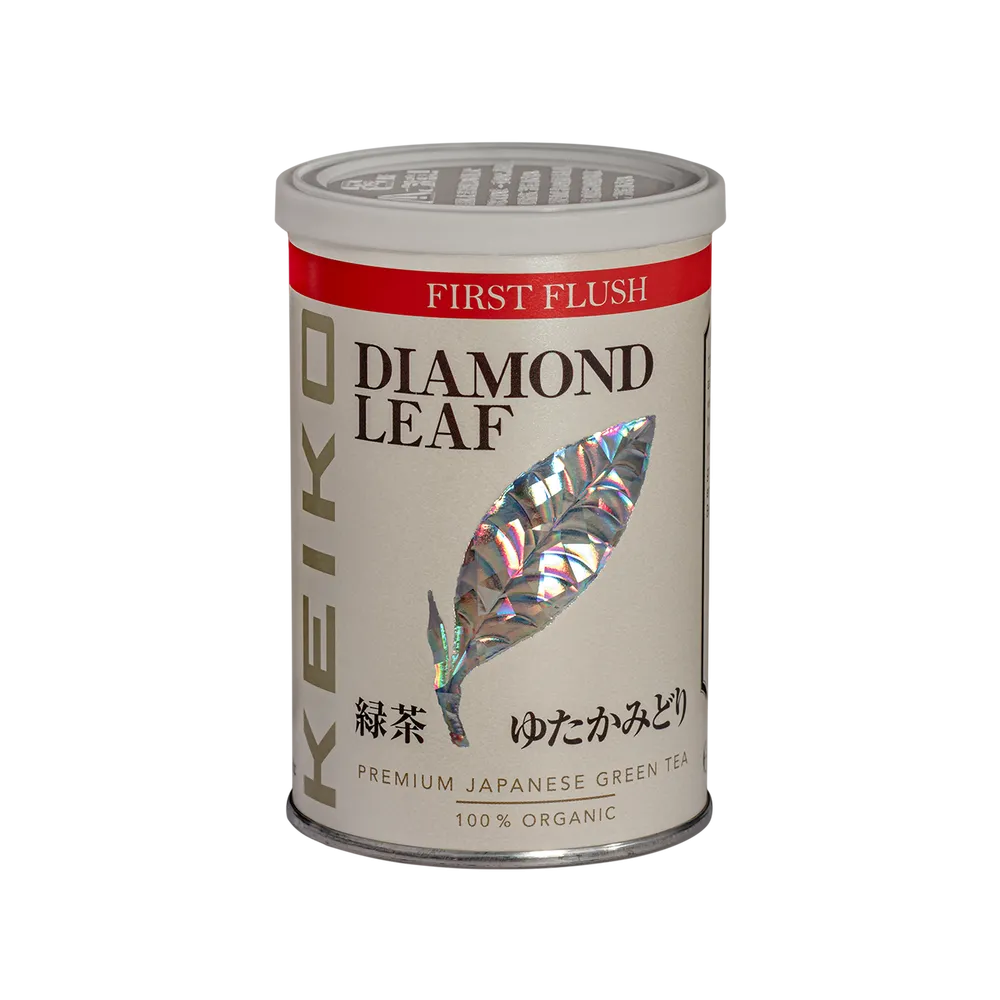

Content: 0.05 kg (€599.00* / 1 kg)

Available, delivery time: 1-3 working days (in Germany)

Average rating of 4.9 out of 5 stars

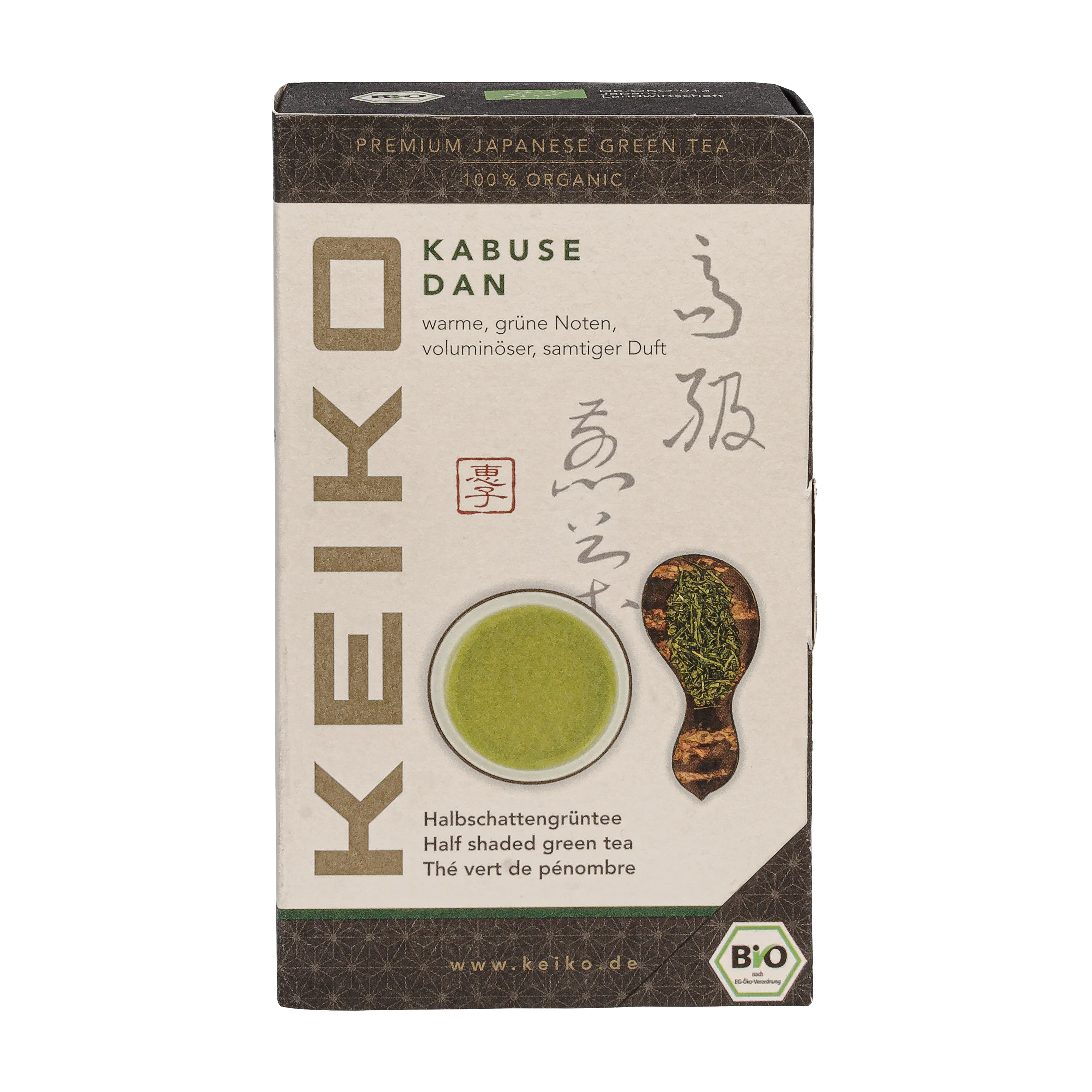

Content: 0.1 kg (€475.00* / 1 kg)

Available, delivery time: 1-3 working days (in Germany)

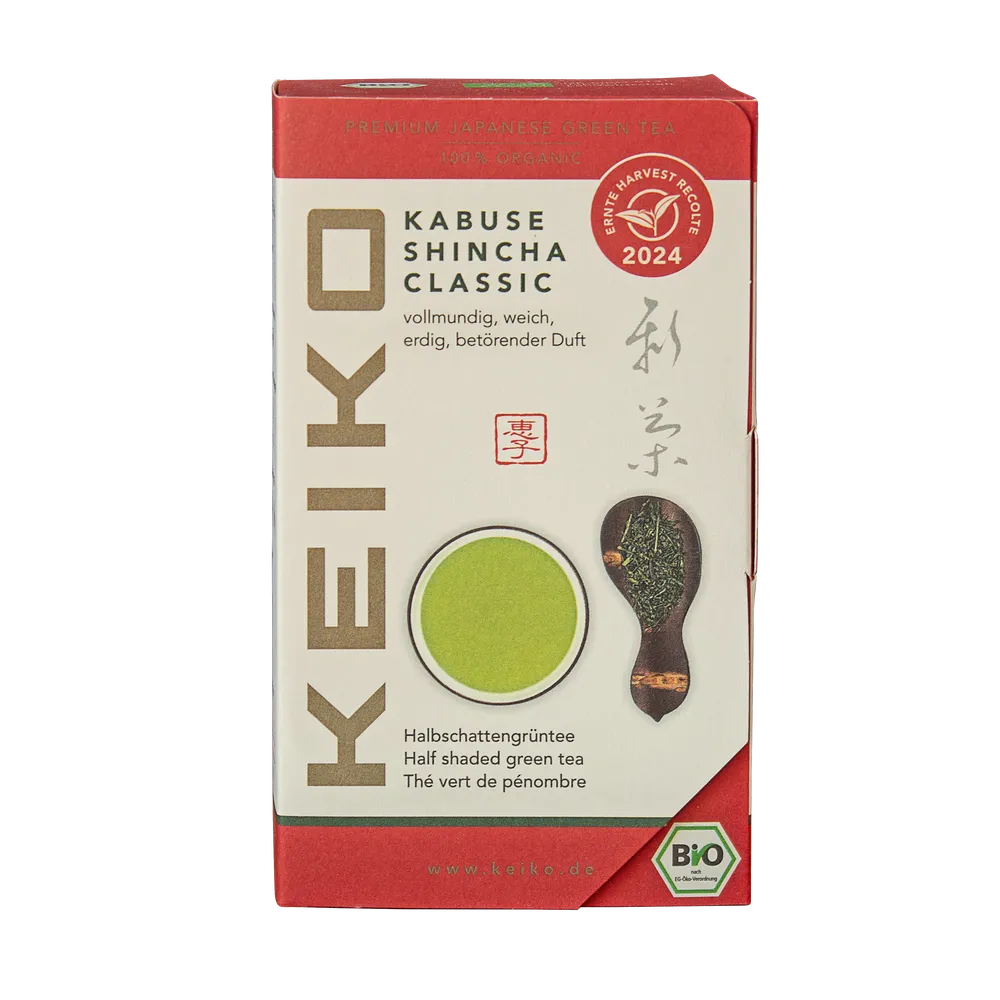

Average rating of 5 out of 5 stars

Content: 0.05 kg (€470.00* / 1 kg)

Available, delivery time: 1-3 working days (in Germany)

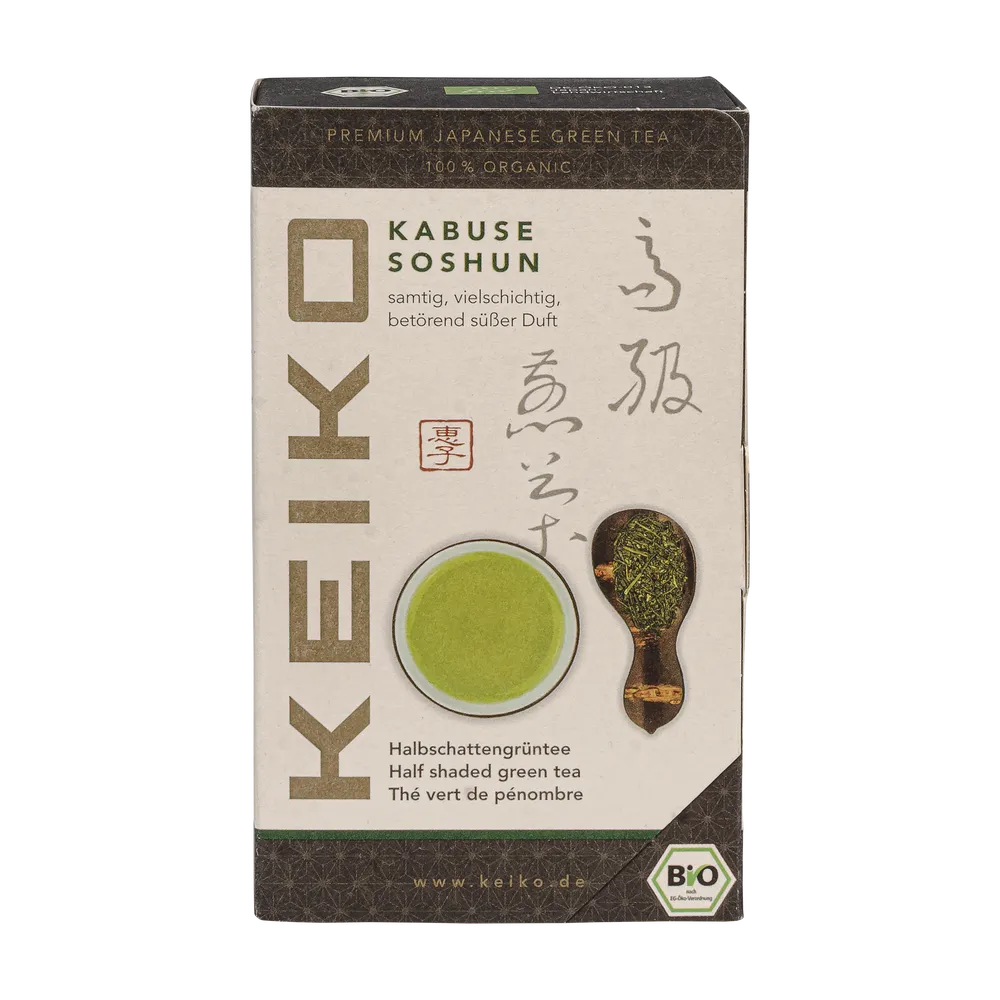

Average rating of 5 out of 5 stars

Content: 0.05 kg (€430.00* / 1 kg)

Not available

Average rating of 5 out of 5 stars

Content: 0.05 kg (€490.00* / 1 kg)

Available, delivery time: 1-3 working days (in Germany)